Reemoon has long been committed to the independent research and development and technological innovation of the product. These excellent systems have greatly improved production efficiency and sorting accuracy for a large number of fruit packaging plants.

● Cope with different types of fruit.

● Have a unique light path design, which penetrates through the pith of the fruit.

● Fast switching module.

● Anti-jamming system.

● High signal-to-noise ratio.

● Low power consumption.

● Quick and accurate.

● Comes withasy to learn and use software.

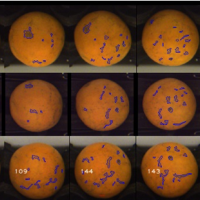

● Detects and identifies oil gland subsidence, lesions, wormholes and impact damage.

● Possesses a unique image processing unit.

● Adaptable to different production environments and customer requirements.

● Dual sensors and four-point contact for accurate weighing.

● Low error rate.

● Automatically switch from two packing mode: packing weight and packing quantity.

● A controllable temperature compensation function.

● Quick fruit cup replacement rate.

● Suitable for sorting both round, and oval, fruits and vegetables.

●Brand new, advanced color recognition methods, adaptive update patented

technology, in the state of high-speed movement of fruits and vegetables, quickly

capture the shape of the fruit, use big data for analysis, and achieve high-precision

color value level analysis. It can be divided into more than ten color grades, which is

suitable for most of the fruits and vegetables on the market.

● State-of-the-art technology that quickly and precisely analyses the shape and color

of fruits and vegetables sorting them into over ten different color grades.

● Advanced defect recognition methods and machine learning reduce fruit wastage. High precision color value analysis separates the fruit and vegetables into over ten color grades, all of which are suitable for the market.

● Reemoon density sorting adapts industrial-grade high-definition camera

and light source system for data collection, which solves the problem of inaccurate

detection accuracy of fruits and vegetables under high-speed operation. It can

accurately calculate the density of fruits and vegetables to achieve refined sorting.

● Accurate density calculation using high-definition cameras and light source systems

allow for refined sorting of fruits and vegetables.

The Reemoon diameter sorting system measures the diameter of the fruit by calculating the dimensions of the fruit and the projected area parameters. The system is flexible and convenient. The user can freely set the range of the fruit sorting diameter, the horizontal and vertical diameter ratio and other parameters.

Reemoon uses three-dimensional imaging technology, high-definition resolution camera and super bright light source system to collect the skin conditions of fruits and vegetables, and uses Gaussian modeling and adaptive update patented technology to process the data, accurate multi-directional image collection, without missing any details,such as pedicle, calyx and navel(umbilicus) of the fruit can also be accurately captured, the collected information can be detected and graded through hybrid Gaussian modeling and adaptive update patent technology. And the core processing modules all use embedded DSP processors, which do not depend on the PC, even if the computer is turned off, the sorting will not be affected at all.

Reemoon’s internal sorting equipment features state-of-the-art technology including advanced gratings and sensor chips with a high signal to noise ratio. It passes light through thick fruit and vegetables to quickly and accurately measure sugar content, acidity, mildew, browning and pulp damage. Modelling is simple and intelligent, with equipment that requires a minimum of debugging time.