The Reemoon cherry sorting line is specially designed for small cherries with many stems and short freshness period. The whole sorting line adopts cold water conveying to maintain a low temperature environment to ensure cherry quality and prolong the shelf life of cherries, which can be sorted and graded for color, size and defects.

Cherries enter the pool from the entrance, the pool is prepared in advance with detergent to remove surface debris, the pool is clean and cold water to prevent the cherries from bumping into each other and damage to the fruit, while filtering out the leaves and stems.

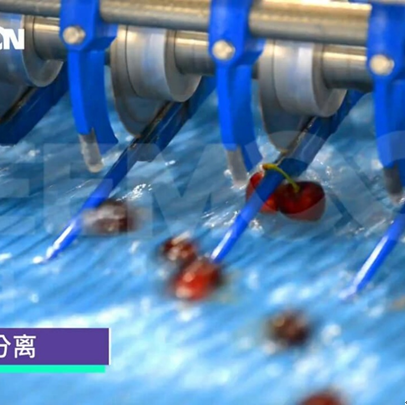

Stem cutter

Rational blade layout and careful protection measures allow the cherry to be separated without damage in the cold water environment.

Elevator and water pool

Re-rinsing the cherries, cold water circulation system to keep the cherries in low temperature sorting, while stepped pre-arrangement of cherries in two arrangements, to improve the upper fruit rate, improve sorting efficiency.

Optical Inspection Systems

Visual identification of cherries and fine sorting of color, size and defects to ensure consistent quality and standardization of cherry sorting.

Air blow down the fruit

Use of compressed air to unload the fruit, no pollution, protecting the cherries from damage.

water tank conveyor

The stainless steel tank conveys the graded cherries and the cold water conveys the cherries in a cold environment to maintain the stability of the cherry quality, and the whole process is visualized to avoid the cherry spoilage due to stagnation.

Chain packing table

Two-stage structure allows for freestanding freshness preservation and reduces the amount of preservatives used. Long selecting table provides quality control stations to ensure high standards of quality and branding.

Fully automatic data collection and processing, from post-harvest to sales, traceability and control.