Reemoon blueberry AI sorting line integrates artificial intelligence, machine vision, and big data analytics to deliver efficient, precise fruit grading and quality control. It empowers clients to upgrade their operations and enhance brand value. The modular, customizable system can be tailored to individual client needs — from small farms to large-scale processing facilities — offering flexibility, scalability, and superior adaptability across all production scenarios.

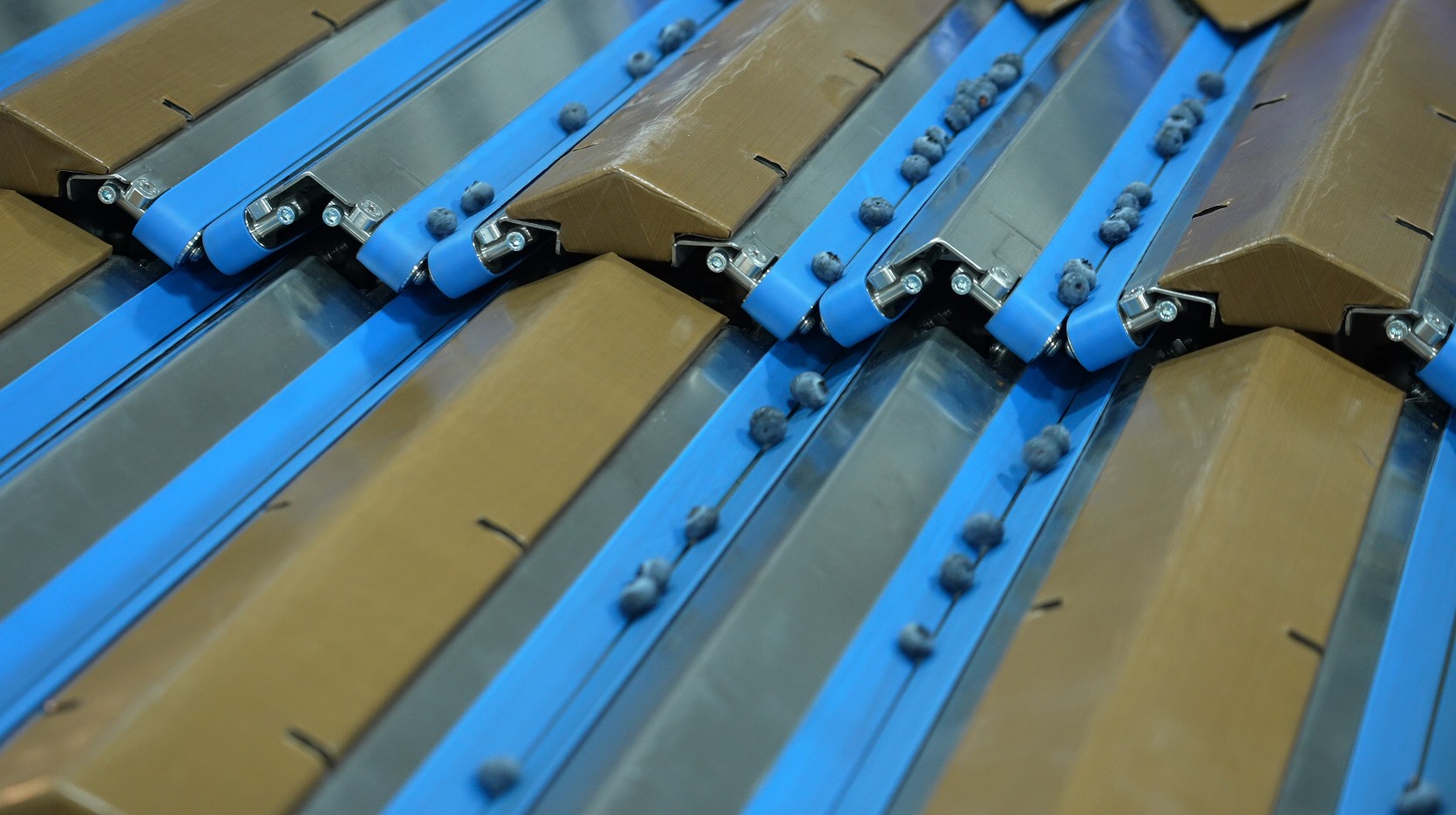

Featuring a flexible, full-process design, the system ensures each blueberry is automatically aligned and positioned for detection, ensuring accurate detection while minimizing fruit bruising or damage.

Equipped with high-resolution industrial cameras and multispectral imaging technology, the system performs a comprehensive detection of each blueberry’s surface to accurately identify defects such as Dehydration, Rot, Scar, Red Berry, Bruises, Crack, Insect Damage, and Mold.

Powerful AI algorithms continuously collect defect data during the sorting process, constantly optimizing the sorting model to achieve self-improvement in sorting accuracy.

Rapid grading based on customized standards enables flexible responses to market demands and meets diverse needs for fresh consumption, deep processing, and export.

The sorted blueberries are packaged by automatic packaging machines, achieving seamless integration of defect sorting, size grading, and quantitative packaging. This process significantly enhances post-harvest efficiency and shortens the time from field to table.

Real-time sorting data enables clients to optimize planting, harvesting, and supply chain management.